2024

ACTEYS®, the story of a beautiful maturity and new ambitions

Completion of the acquisition of the company by Didier CINQUIN

and the creation of ACTEYS®

Drafting of the ACTEYS® manifesto

—

Validation of the Patent in Canada.

Operational Excellence Trophy awarded by TOPTECH.

Launch of the ISO 9001 certification process.

Recruitment of a sales force in France.

Inclusion in the #10KSFrance program by Goldman Sachs

Participation in the INTERMAT 2024 trade show.

Redesign of the Information System – IS.

2023

Validation of the Patent in France and in 25 European countries.

Allier Business Trophy – 1st prize – Innovation category.

Major transformation of the operational organization.

2022

Surge in costs and raw materials…

Rollout of an operational excellence approach with TOPTECH to optimize production and find internal margins.

Filing of the Patent in North America.

First international contracts signed with Canada.

2021

Commercial Development through Product Innovation!

Launch of a new hydraulic coupling for foundry TRIGGER System®,

Filing of the new Patent in France and Europe.

Commencement of export prospecting in Canada.

2020

Keep the direction ! Against all odds…

It was without counting without a new crisis, “health” and “economic” which upsets the certainties and obliges the company to a new questioning of its organization … And yet the economic model of the company holds good and confirms its resilience.

The manager’s vision, the support and commitment of the teams make it possible to create emergencies in this crisis situation. The projects are progressing despite everything … and the course is held.

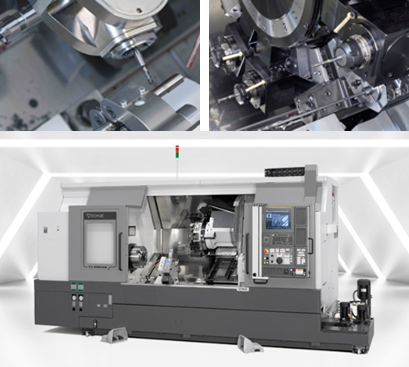

Among the new investments made, a CMZ – TD-30-Y-1350 / Fanuc 32iTB lathe reinforces the machining capacity.

2019

In continuity … and towards new ambitions.

Didier CINQUIN takes over the presidency of the company on September 20, 2019 and pursues the industrial and commercial development strategy, in line with the years spent under the presidency of Philippe JANDARD (partner and CEO of ACB PUME).

Focused on new export ambitions, Didier CINQUIN is stimulating a new dynamic and initiating many projects towards the digitization of data and digital, with the creation of a new graphic identity, a new website.

2018

For 10 years… How time goes on !

19th July 2018, ACB PUME celebrates its 10 years !

During a nice sunny day, the staff and its managers together as many as a hundred persons celebrate their succeed along all these work years, with doubt and perseverance.

Somes figures over these ten years… ! ACB PUME has delivered to its sister Company ACB over than 92 000 buckets, has manufactued over than 1500 agricultural attachements, and over 900 T of casting-parts….

« Success is a track made available due to patience and work… » Pierre Simon Ballanche

2017

Investments and projects !

TRIGGER System ® is developped with the TS-H (hydraulic coupler with self-adjustments) that completes the products range !

Designed for excavators higher than 8T, it is adjusted to the TRIGGER standard measures and to the OEM measures.

The Company goes on the improvement of its production equipment, for better results, efficiency and safety with :

- A new NC automatic SAW (Kasto win 3.3),

- A fifth welding robot (Rti 330 Igm),

- A plasma MESSER folding cutting machine equipped with a HPR260 and a True Hole technology,

- A machining Center (HYUNDAI F650/BT60).

2014

Expans and advance… turnover as high as 4.7M€

The Company goes on its industrial and commercial development, with projects and a shown desire to succeed !

Due to too narrow facilities, the Company creates new offices (compliant with RT2012-area 180m²) and a new workshop (area 480m²) in which the 4th welding robot is placed (Rti 476S Igm).

2013

Innovation is at the center of our projects !

TRIGGER System® – patent application and brand mark

To be compliant with the standard evolution, the Complany designs a new TRIGGER System ® coupler and applies for an innovation patent that improves safety and comfort during manual attachement changes.

2011

The activity increases… +62% and a turnover as high as 3.3M€ .

« They didn’t know it was impossible, so they did it » – Mark Twain

The Company has a such organization that everybody is satisfied, and especially the customers who confirm their confidence and increase their involvments.

In this continuous improvement philosophy, the Company buys a 3rd welding robot (OTC DR4000) and impove its manual welding tools.

2010

Believe in the future, be organized and succeed… !

The staff and Managers are together overall effort and stand against adversity and doubt.

the Company « adjusts » its production area, reorganizes the industrial production on the first location, implements shift wok and optimizes production flows.

New investments are made… among others an folding machine (ERMAK 320T -4m) and a 2nd welding robot (MOTOMAN SK16).

2009

Crisis management and improvement of production means.

The financial and economic crisis from 2008(09) has not spared the recently established Company who must face this never-seen-economic situation and must deploy of ressources and of work organisation.

Despite of it, investments are made to upgrade production means by purchasing a PLASMA MESSER cutting machine equipped with a HT2000 and with the first welding robot (FANUC RJ3iB).

2008

Creation of ACB PUME Company and reversal of PUME Company asset (Saint Victor 03).

ACB PUME Company, created and led by Philippe JANDARD (ACB) takes over the historical activity of PUME Company, famous in buckets and couplers manufacture.

Didier CINQUIN, its General Director leaves LCB Complany (Régnié Durette 69), is involved to lead the Company, to improve the oranization and the industrial development by increasing sub-constracting for famous industrial manufacturers.